Small and medium-sized enterprises (SMEs) face increasing challenges in managing production schedules due to supply chain disruptions, outdated tools, and complex operations. AI production scheduling offers a faster, data-driven alternative to manual methods, enabling SMEs to optimize resources, reduce costs, and improve delivery performance. Key benefits include:

- Faster Scheduling: Cuts schedule creation time by up to 90%.

- Cost Savings: Reduces scheduling costs by 5–15%.

- Improved Efficiency: Minimizes changeovers and boosts productivity.

- Real-Time Adjustments: Adapts instantly to disruptions like machine breakdowns or rush orders.

For instance, companies like Blount Fine Foods reduced waste by 35% and increased production efficiency by 2% using AI-powered tools. Transitioning to AI involves assessing business needs, preparing data, training staff, and selecting the right deployment model (e.g., cloud, on-premises). Start small with a pilot project and track KPIs like equipment utilization, on-time delivery, and throughput to measure success.

AI doesn’t replace planners - it supports them by automating repetitive tasks, allowing teams to focus on higher-value decisions. With 58% of supply chain businesses planning to invest in AI, now is the time to consider integrating these tools into your operations.

Advanced Production Scheduling with AI Assistants | Efficient Manufacturing & Production Planning

sbb-itb-bec6a7e

Key Features of AI Production Scheduling Tools

AI production scheduling tools offer three main capabilities that reshape how small and medium-sized enterprises (SMEs) handle their operations. These features work together to create schedules that adjust to real-world challenges while focusing on efficiency and cost-effectiveness.

Predictive Analytics for Demand Forecasting

AI uses historical sales data, real-time point-of-sale (POS) inputs, ERP systems, and even weather data to deliver highly accurate demand forecasts. Unlike static spreadsheets or simple averages, AI algorithms uncover patterns in supply chain data that are often missed by manual methods. This shift allows SMEs to move from reactive problem-solving to proactive planning.

The impact is clear. For instance, in 2024, Atria, a leading meat supplier in Northern Europe, adopted machine learning to process complex retail partner data. Under the guidance of Tapani Potka, SVP of Delivery Chain Management, the company achieved an impressive 98.1% weekly forecast accuracy while cutting manual forecast adjustments by 13%.

"Following the introduction of machine learning, we were extraordinarily impressed to see just how much further RELEX algorithms could improve our forecast accuracy and stability - improvements critical to our ability to manage the complexity specific to our industry and business model." - Tapani Potka, SVP, Delivery Chain Management, Atria

Once AI delivers precise forecasts, it seamlessly shifts to handling unexpected disruptions in real time.

Real-Time Monitoring and Dynamic Adjustments

When unexpected events occur - like equipment failures, rush orders, or material delays - AI systems quickly recalculate schedules in seconds. Instead of requiring planners to start from scratch, these tools suggest minimal adjustments that maintain stability and honor delivery deadlines. By processing real-time data from IoT sensors, machine health monitors, and POS systems, AI translates disruptions into actionable production updates.

Blount Fine Foods, a fresh prepared foods manufacturer, showcased this functionality in 2023. By linking manufacturing constraints with sales forecasts across roughly 1,500 SKUs, the company reduced finished goods waste by 35% and boosted production efficiency by 2% through optimized scheduling that minimized changeovers. Meanwhile, a national steel manufacturer achieved a 99% reduction in scheduling time, increased production by over 1,000 tons of finished goods, and gained $4 million annually in benefits.

Constraint-Based Optimization

AI systems can process thousands of variables simultaneously - accounting for machine capacity, labor availability, material supply, changeover times, and delivery deadlines. This constraint-aware scheduling ensures that plans are not just theoretically ideal but also feasible within real-world limitations. Advanced systems even provide detailed "evidence packages" that explain cost drivers and production bottlenecks, helping planners trust the AI-generated schedules.

For SMEs in industries like food production, where shelf life and ingredient costs are critical, AI can optimize schedules to align with these unique needs. Tegel Foods in New Zealand, which processes over 50 million birds annually, transitioned from Excel-based planning to AI-driven scheduling. Arijit Saha, General Manager of Supply Chain, shared that the system now delivers weekly production targets with daily demand breakdowns, allowing the company to anticipate shortages and optimize line sequencing to increase throughput.

"AI in production planning helps you define what a 'good' schedule looks like, offers intelligent options, and allows your team to make the final call." - Phantasma Labs

How to Implement an AI Production Scheduling System

Shifting from manual planning to an AI-driven scheduling system doesn't mean turning your operations upside down. Many small and medium-sized enterprises (SMEs) have successfully transitioned by following a step-by-step approach that delivers results at each phase while boosting team confidence.

Assess Your Business Needs and Set Goals

Start by identifying the weak spots in your current scheduling process. Are last-minute orders throwing everything off balance? Do equipment failures force you to constantly rework schedules? Is excessive changeover time eating into your production output? These are the kinds of inefficiencies that AI can help resolve.

Once you've pinpointed the problem areas, set clear goals and measurable success metrics. For example, you might track improvements in on-time delivery (OTD) rates, throughput, or reductions in setup times. A great example is Lenovo's AI-powered Advanced Production Scheduling (APS) project. In December 2023, Bai Zhizhi, Senior Manager of Order Management, and IT Manager Haiming Gan led an implementation that produced impressive results: schedule creation time dropped from two hours to just two minutes, production capacity increased by 24%, and on-time deliveries improved by 3.5 times.

To ease into the process, begin with a pilot project on one production line or product family. This allows your team to test the system in a controlled environment, understand its potential, and see concrete benefits before scaling up. Once you've established your objectives, the next step is to ensure your data is ready for integration.

Prepare and Integrate Your Data

For AI scheduling tools to work effectively, they need four key types of data: orders (quantities and deadlines), routings (operation steps, setup times, and run times), resources (machine capacities and schedules), and shift models (labor availability). The good news? You don’t need flawless data to get started. Modern AI systems, especially those using reinforcement learning, can train on digital factory models and simulate thousands of scenarios, even without extensive historical data.

The priority here is to integrate the AI system with your existing tools, such as your ERP, Manufacturing Execution System (MES), or Supply Chain Management (SCM) software. This ensures that schedules are generated using accurate, real-time data, eliminating the need for manual inputs.

Standardizing your data is equally important. For example, calculate key metrics like machine downtime rates, material lead times, and employee productivity. These insights help the AI make better decisions. Additionally, set up a feedback loop where production results and user adjustments are fed back into the system. This allows the AI to continuously improve its predictions and stay aligned with real-world shop-floor conditions. Once your data is in shape, focus on preparing your team for the change.

Train Staff and Manage Change

Even the best technology can fail if your team isn’t on board. To address this, position AI as a "co-pilot" rather than a replacement. Planners will move from tedious tasks like manual data entry to more strategic roles, such as overseeing schedules and managing exceptions.

Building trust is key. Use explainable AI features to show your team why the system generates certain schedules. When planners can see the reasoning behind decisions - like cost drivers or bottlenecks - they’re more likely to embrace the tool. Encourage them to experiment with "what-if" scenarios to understand trade-offs and appreciate the AI’s analytical power.

Lenovo’s success with their AI scheduling system highlights the importance of early stakeholder involvement. By engaging employees from the start, they achieved a 95% adoption rate. Additionally, equip shop-floor operators with real-time visibility tools, like live scoreboards or digital interfaces. This ensures they can see schedule updates immediately and understand their new priorities. When everyone, from planners to operators, sees how AI supports their work rather than replacing it, the transition becomes much smoother.

Deployment Options and Selecting the Right Solution

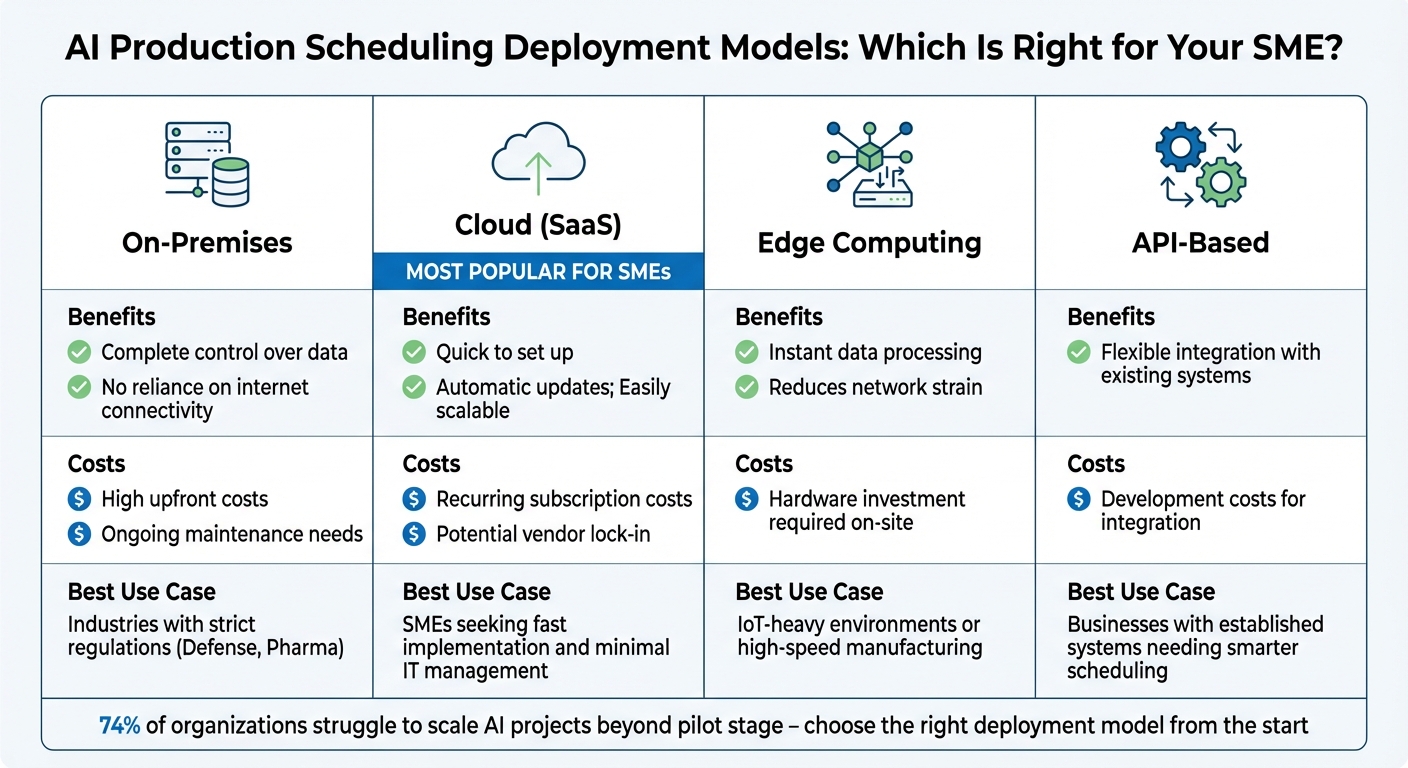

AI Production Scheduling Deployment Models Comparison for SMEs

Deployment Model Comparison

Once your data is prepared and your team is trained, the next step is choosing the right deployment model. Small and medium-sized enterprises (SMEs) have several options, each with its own balance of cost, control, and complexity.

| Deployment Model | Benefits | Costs | Best Use Case |

|---|---|---|---|

| On-Premises | Complete control over data; no reliance on internet connectivity. | High upfront costs; ongoing maintenance needs. | Industries with strict regulations, like Defense or Pharma. |

| Cloud (SaaS) | Quick to set up; automatic updates; easily scalable. | Recurring subscription costs; potential vendor lock-in. | SMEs seeking fast implementation and minimal IT management. |

| Edge Computing | Instant data processing; reduces network strain. | Hardware investment required on-site. | Ideal for IoT-heavy environments or high-speed manufacturing. |

| API-Based | Flexible integration with existing systems. | Development costs for integration. | Businesses with established systems needing smarter scheduling capabilities. |

For most SMEs, cloud-based (SaaS) solutions are the go-to choice. They eliminate the need for costly servers and IT teams by outsourcing infrastructure, updates, and scaling to the provider. This allows businesses to concentrate on production rather than technical upkeep.

If your operations depend on IoT devices and require real-time adjustments, edge computing might be a better fit. By processing data locally, edge systems minimize latency and prevent network overload. However, this option does involve additional hardware investments for each production line.

For companies with existing ERP or MES systems, API-based solutions can add advanced AI scheduling without requiring a complete system overhaul. This modular approach is perfect if your current tools meet your needs but lack built-in AI capabilities.

With these deployment models in mind, the next step is to evaluate which one aligns with your business's readiness and growth potential.

What to Consider When Choosing a Solution

After exploring deployment options, it’s time to focus on selecting an AI scheduling tool that fits your technical and operational requirements.

Start by evaluating your technical readiness. If your IT resources are limited, opt for SaaS platforms with user-friendly interfaces and low-code setup options. Research shows that nearly 74% of organizations struggle to scale AI projects beyond the pilot stage, and up to 90% of AI models fail to reach full deployment due to technical and structural issues. Choosing a solution that aligns with your team’s expertise can significantly improve your chances of success. Look for tools that integrate seamlessly with your existing ERP systems, such as SAP, Oracle, or NetSuite, and automatically pull in critical data like orders, routings, resources, and shift models.

Data security should also be a top priority. Select a provider that safeguards your production data and avoids sharing it with third parties to train their models. Providers adhering to strict ethical AI standards are a safer choice. If data sovereignty is a concern, consider a "Bring Your Own Cloud" (BYOC) approach, where the AI software operates within your own cloud account (e.g., AWS or Azure). This gives you control over your data while still benefiting from managed services.

Lastly, ensure the solution can grow with your business. Companies using specialized AI platforms report a 40% faster time-to-market for their AI-driven products. Choose a system that can handle increased production volumes, new product lines, or additional facilities without requiring a complete overhaul. Starting with a small, focused pilot is a smart move, but make sure the platform can scale as your needs - and confidence - expand.

Measuring Success and Improving Over Time

Key Performance Indicators (KPIs) to Track

After deploying AI solutions, it’s crucial to measure their impact using clear and actionable metrics. Start by keeping an eye on equipment utilization, throughput, and changeover times to evaluate how well resources are being used. On the customer service side, metrics like On-Time Delivery (OTD) and On-Time In-Full (OTIF) rates can provide valuable insights. For instance, advanced AI-driven planning has been shown to improve on-time delivery rates by up to 20% while maintaining strong fill rates.

Another essential metric is planning productivity. AI can drastically cut down the time required to create production schedules - by as much as 90%. Take MAAG Food in Estonia as an example: by implementing AI-driven forecasting for over 300 SKUs, they hit 96% demand forecast accuracy without manual adjustments, boosting their overall planning efficiency by 22%.

Financial performance should also be part of your analysis. AI-driven scheduling can lower scheduling costs by 5–15% and improve resource utilization by approximately 25%. In industries dealing with perishable goods, the benefits are even more pronounced. For example, Blount Fine Foods reduced finished goods waste by 35% and increased production efficiency by 2% across 1,500 SKUs after adopting AI scheduling in 2023.

Tracking these KPIs not only measures success but also highlights areas for ongoing refinement.

How to Continuously Improve Your System

Tracking KPIs is just the beginning - sustained success requires ongoing fine-tuning. Establish a feedback loop between your AI system and the shop floor. This means regularly collecting data on production outcomes, machine downtime, and operator feedback to adjust algorithms as conditions change. It’s also essential to monitor data quality and run periodic "what-if" scenarios to refine parameters and achieve the right balance between cost, speed, and resource use.

To make the most of your AI system, shift planners toward more strategic roles. This includes reviewing AI-generated trade-offs, managing exceptions, and identifying inefficiencies that might escape the system’s notice. Regularly auditing data quality is equally important - update inputs like machine capacities, maintenance schedules, and labor availability to ensure the AI’s decisions remain aligned with current operational realities.

Conclusion: Getting Started with AI Production Scheduling

You don’t need to overhaul your entire operation to start using AI for production scheduling. Instead, begin small with a focused pilot program - try implementing it on one production line or a specific product family. This targeted approach helps you quickly show results, build team confidence, and avoid the risks of a sweeping transformation. Use core data from your existing ERP or MES systems, such as orders, routings, resources, and shift models, to get started. This step lays a solid foundation for integrating AI as a valuable partner in your operations.

Think of AI as a co-pilot, not a replacement. While AI excels at crunching numbers and generating optimized schedules, human planners remain key for strategic decision-making and addressing exceptions. This teamwork often leads to tangible benefits like reduced waste and improved production efficiency.

To ensure success, define clear metrics from the start. Whether your goal is better On-Time Delivery, shorter changeover times, or higher throughput, having measurable KPIs helps track progress and justify further investment. Many factories report seeing a return on investment (ROI) within just six months. By focusing on metrics, you set the stage for scalable improvements that align with your broader operational goals.

Seamless integration with your current systems is also crucial. The right AI solution should complement your ERP, enabling smooth data flow and real-time schedule updates. Look for tools that offer "what-if" scenario analysis and shop floor visibility, so operators can quickly adapt to schedule changes. With 58% of supply chain companies planning to invest in AI over the next five years, now is the perfect time to explore your options.

For more information and curated AI scheduling tools tailored to small and medium-sized businesses, visit AI for Businesses.

FAQs

How can AI production scheduling help my small or medium-sized business?

AI-driven production scheduling is changing the game for small and medium-sized businesses (SMEs) by streamlining operations like never before. By processing real-time data - such as demand forecasts, inventory levels, machine availability, and workforce capacity - AI creates schedules that can adjust on the fly. Whether it's an unexpected equipment breakdown or a last-minute rush order, these tools help keep workflows smooth, minimize delays, and cut down on waste.

For SMEs, the advantages are hard to ignore. AI solutions can seamlessly integrate with your current systems, eliminating the need for expensive overhauls. This means you can boost efficiency, lower operational costs, and give your team more time to focus on high-value tasks. The payoff? Improved cash flow, better on-time delivery performance, and the flexibility to grow your operations as your business expands. Plus, with budget-friendly and scalable options available, you can start small, see results, and scale up when you're ready.

How can I successfully implement AI-driven production scheduling in my small or medium-sized business?

To get started with AI-driven production scheduling, the first step is to pinpoint your goals. Ask yourself what specific issues you’re aiming to solve. Are you looking to cut down on late deliveries, make better use of your production lines, or lower scheduling costs? Define clear, measurable objectives and keep in mind any limitations, such as shift patterns or equipment capacity.

Once your goals are set, focus on gathering and cleaning your data. This means ensuring you have accurate and up-to-date information about production orders, demand forecasts, inventory levels, and labor schedules. The quality of your data is critical - AI systems rely on this to learn and function effectively. Afterward, select an AI scheduling tool that works seamlessly with your current systems, allows for real-time updates, and fits within your budget. To minimize risk, start small by running a pilot project. Use this as an opportunity to test the tool and fine-tune it before rolling it out across your operations.

The final step is to prepare your team. Make sure they know how to use the AI tool efficiently, and keep an eye on key performance metrics like schedule accuracy and cost savings. Be ready to tweak and improve the system as needed. By taking these steps, you’ll position your operations for smoother workflows and better overall efficiency.

How can I select the best AI scheduling tool and deployment model for my business?

To find the best AI scheduling tool for your business, start by clarifying what you need it to accomplish. Are you trying to cut down on overtime costs, improve delivery times, or handle unexpected demand spikes more effectively? Be specific about your goals - like saving $5,000 a month or increasing production efficiency by 10%. Also, make sure the data you plan to use, such as inventory records, machine logs, or employee schedules, is well-organized and ready for analysis.

When comparing tools, think about a few key aspects: how well they integrate with your current systems, whether they can grow with your business, how easy they are to use, and, of course, if they fit your budget. Tools that include explainable AI - which breaks down the reasoning behind scheduling decisions - can also help your team feel more confident in adopting the system.

For implementation, cloud-based SaaS solutions are often a great fit for small and medium-sized businesses because they come with lower upfront costs and automatic updates. That said, if you're concerned about data privacy or need faster processing, you might want to explore on-premises or hybrid options. By aligning the tool and its deployment method with your specific needs, you’ll set yourself up to get the most out of AI scheduling.